The first building block that

eats CO2 straight from the source

The co2ncreat project brings to the European construction sector a new range of innovative building materials with a negative carbon footprint. The co2ncreat block offers avenues to decarbonize future construction projects.

co2ncreat is an innovative project, where CO2 and secondary raw materials (aggregates) are used to produce eco-friendly masonry blocks.

100,000 tonnes

An annual production of more than 100,000 tonnes of eco-friendly masonry blocks.

12,000 tonnes

12,000 tonnes of CO2 captured, transported over 2 km and used each year in the blocks

8,000 tonnes

8,000 tonnes of CO2 avoided each year through the use of secondary aggregates.

4 partners

4 Belgian stakeholders join forces to participate to the decarbonization of the Belgian industry and offer a sustainable solution to the construction sector.

Capture and conditioning of flue gases

Instead of the traditional cement used in masonry blocks, CO2 will be our binder!

This CO2, a co-product of the production of lime, is present in the Lhoist flue gases. It comes from the transformation at high temperature of limestone taken from our quarries into lime and from the combustion process.

Transport of flue gases by pipeline

A 2 km pipeline built and operated by Fluxys will connect Lhoist to Prefer crossing a railway line and a river. It will enable the transport of Lhoist flue gases to the Prefer manufacturing unit in order to permanently sequestrate the CO2 contained in the flue gases into useful masonry blocks.

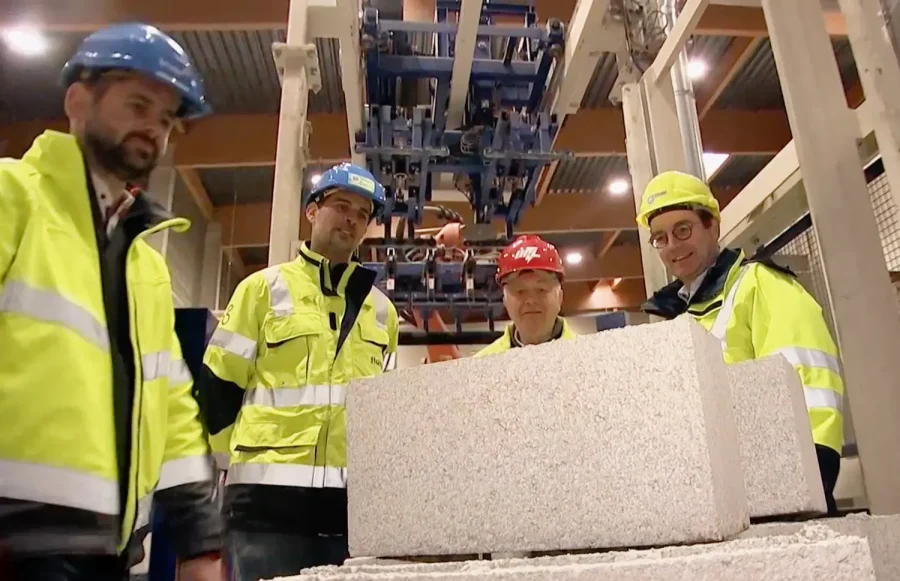

Manufacturing of blocks

We not only valorize CO2 but also slag, a non-metallic by-product of the stainless steel industry which is created following the addition of lime to capture silica. Slag is a substance which loves CO2 and which can be used as aggregates in masonry blocks. These secondary raw materials will be transported in barges from Orbix to the Prefer production plant.

Prefer will mix these aggregates to get the best particle size distribution for a quality surface and compact them into the desired block format.

Curing of blocks by carbonation

In the curing room, the blocks are exposed to Lhoist flue gases - containing CO2 - and are carbonated using the Carbstone® technology developed by Orbix. In this carbonation process, CO2 together with calcium act as a binder for the secondary aggregates and is forever transformed into calcium carbonates, just as in natural stone.

During this hardening step, our co2ncreat building products literally eat CO2. co2ncreat blocks meet all the expectations of the market. They can be used by bricklayers in the same way as conventional blocks, thanks to their similar technical and aesthetic properties.

Cycles

Double circularity

Using CO2 gas from the lime plant and slag, a by-product from the steel industry, the result is “double circularity” allowing production of carbon negative blocks

Actualities of the project

Consortium

4 Belgian industrial partners

The co2ncreat project is born from the industrial symbiosis and complementarity of four Belgian companies that decided to form a strong partnership based on innovation and CCU (Carbon Capture and Utilization).

Raphaël Grimont

Managing Director at Prefer

As market leader, we must ensure the sustainability of our business by offering innovative and eco-friendly products to our customers. With the co2ncreat project, our building materials will be produced through a sustainable and efficient process and based on local, circular raw materials. The Prefer masonry block of tomorrow will retain all the advantages of the traditional block, with the difference that it will benefit from a negative carbon footprint. We are proud to develop this exceptional project together with key industrial partners while benefiting from the trust of the European, Belgian and Walloon authorities.

Pascal De Buck

Managing Director and CEO of Fluxys Belgium

Fluxys is proud to leverage its expertise in the construction and operation of pipelines to contribute to the innovative co2ncreat project and the circular economy. The project fully fits with our green transition strategy, offering CO2 emitters the possibility of transporting their captured CO2 through pipelines. That is how we contribute to industry decarbonisation solutions that are essential to achieve climate change objectives and ensure the long-term viability of the economy.

Vincent Deleers

General Manager Lhoist Western Europe

The project fits perfectly with our willingness to actively develop CO2 capture and sequestration technologies that are essential to the sustainability of our industry. We are delighted that our work on innovative solutions has been recognized by the European Innovation Fund and we look forward to working with our partners to bring co2ncreat to the next level.

Serge Celis

Director of Orbix

We are delighted to implement the co2ncreat project with our partners. This project is the culmination of many years of research by Orbix into its Carbstone® technology. The co2ncreat project involves manufacturing cement-free masonry blocks using industrial fumes. Our blocks store CO2 permanently. They are blocks with a negative carbon footprint. Co-products from steelmakers and lime producers are valorized in a joint product. Synergies like these strengthen local industry. We are very grateful to Europe for supporting us in this through the Innovation Fund.

Project supported by the European Union

The project is funded by the European Union through the Innovation Fund Small Scale (grant agreement 101103194).

The Innovation Fund is one of the world’s largest funding programs for the demonstration of innovative low-carbon technologies.

Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the granting authority, the European Climate, Infrastructure and Environment Executive Agency (CINEA). Neither the European Union nor the granting authority can be held responsible for them.